Have you heard of 5S? It is a way to organise a workplace that started in the Toyota factories in Japan post World War 2. A little like a war, COVID-19 has turned many business practices upside down with tremendous subsequent stress. Perhaps it is worth visiting the 5S concepts to see how waste and inefficiencies can be minimised and regain some control of our workplaces.

5S Concepts

Here is our understanding of the 5S system and how it relates to Linemarkers South East Queensland over the last few weeks. 5S stands for five words in Japanese that start with the letter S. Happily, for those of us who don’t speak Japanese, there are five words starting with S in English that relate. Here they are with the word Japanese first and English second.

Seiri/Sort

Sort through the workspace and work out what is needed for the tasks involved and what can go because it isn’t needed. As businesses develop, there are always bits and pieces of kit that is kept but not used. This is ideal for those quiet business times where staff can be kept busy on something worthwhile to the business. We weren’t necessarily quiet just lately but as fate would have it, we at Linemarkers South East Queensland have just moved to new work premises at 119 Gardens Drive, Willawong. After nearly twenty years in businesses, there was plenty of gear that was a ‘must have’ at the time, but irrelevant to current work practices. The Seiri/Sort process was integral to setting up our new shed and office space.

Seiton/Set in Order

With our move, part of the process was to set in order all the tools and equipment that we had sorted and transported over. We wanted logical and safe processes for use of the items. A few examples. We spent time reflecting on the flow of work including deliveries made to our shed, such as our Dulux Roadmaster A1 paint. Similarly, Planet Paints pick up our used gun wash and surplus paint for recycling. We now have a designated area for this to ensure efficient product handling.

Seiso/Shine

Keeping the workplace clean and tidy maintains the efficiencies gained in work practices. This is just common sense, but when busy it is easy to let tidiness slip. Of course, our new shed shines because we have just arrived. It is shining too because we are vigilant in our cleaning due to COVID-19. Whilst quiet, it is also a great opportunity to keep staff busy doing maintenance tasks, so equipment is ready for when the work ramps up again.

Seiketsu/Standardise

Management has a role here. Standards are to be set, and formalised. At Linemarkers South East Queensland we do that with our Standard Operating Procedures. That way everyone knows our standardised procedures from how to run an airless spray gun to painting a pedestrian crossing.

Shitsuke/Sustain

Sustain the new practices over time but also review them. Are they working? What can be done better? Is that piece of equipment necessary, or can we downsize some more? We have already done this in our new shed!

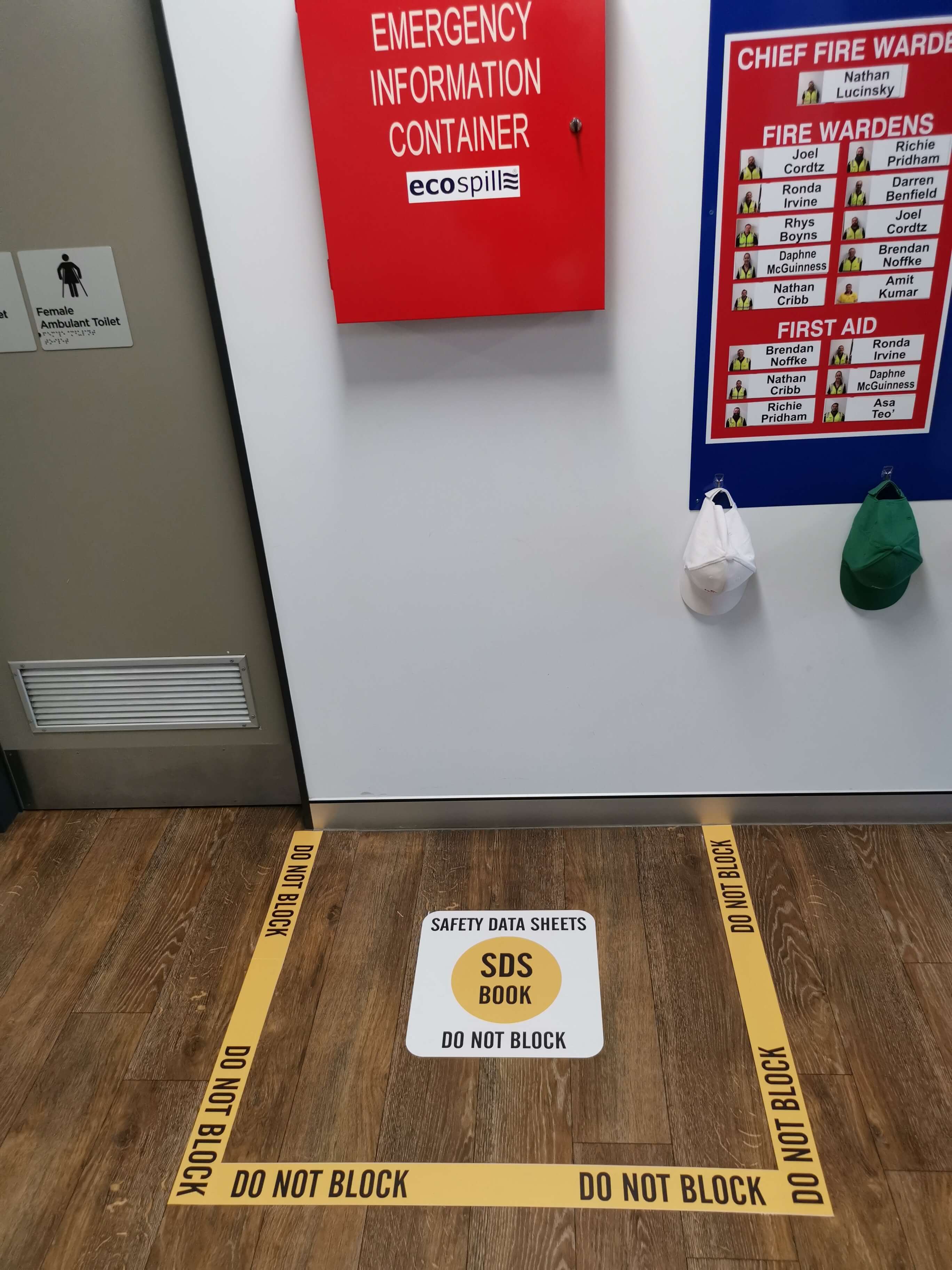

Safety

There is a sixth S and that is safety. This is where Linemarkers South East Queensland can help your processes. We have already supplied and installed some specialised visual management stickers and floor markings at a distribution warehouse. It could be said though, that every forklift traffic area logo, walkway edge line, and pedestrian crossing that we paint is a visual safety message and therefore part of the 5S process.

Linemarkers South East Queensland

If you would like to have some safety stickers manufactured and installed, refresh your existing line marking or paint new safety messages due to a change in your workflow, please give Stacey in our office a call on 07 3277 2448 or use our contact form. Now is a great time to prepare your workspace for what we all hope will be a prosperous and busy future.